Fluorescent Brightener for Textiles Industry in Gujarat

Table of Contents

Gujarat, the hub of India’s textile manufacturing, is witnessing a growing demand for Fluorescent Brightener for Textiles Industry in Gujarat. This demand surge stems from the need for brighter, cleaner, and high-quality fabrics across cotton, polyester, and blended textile materials. Fluorescent brighteners, also known as Optical Brightening Agents (OBA), are playing a pivotal role in enhancing the visual appearance of fabrics by reducing yellowing and increasing whiteness. Fluorescent Brightener For Textiles Industry In Gujarat

Explore:

Optical Brightening Agents for Paper Industry in Gujarat

In this article, we will explore why Gujarat is a leader in the textile chemical sector, how fluorescent brighteners work, and their different applications in cotton and polyester fabrics. We’ll also look into top manufacturers, and key benefits of using these chemicals in textile processing.

Understanding Fluorescent Brightener for Textiles

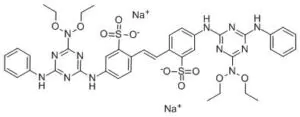

Fluorescent brighteners are synthetic chemicals that absorb invisible ultraviolet light and emit visible blue light. When applied to fabrics, they enhance the whiteness and brightness by offsetting the natural yellowish tinge that comes from processing or aging. In a region like Gujarat, where the textile industry is one of the key contributors to the economy, the use of Fluorescent Brightener for Textiles Industry in Gujarat is becoming essential for meeting global quality standards.

Optical Brightening Agent for Cotton Fabric

Cotton is the most widely used natural fiber in the textile industry, and Gujarat is one of India’s leading cotton-producing states. However, cotton fabric often exhibits a dull, yellowish appearance after bleaching or washing. To address this, textile processors rely on optical brightening agent for cotton fabric to improve the fabric’s whiteness and aesthetic appeal.

OBAs for cotton are specially formulated to bond with cellulose fibers and are stable under high temperatures and varying pH levels. When applied correctly, they not only enhance the whiteness but also increase the perceived value of the finished garment or textile product. These agents are used in stages such as finishing, dyeing, or even before printing.

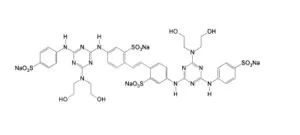

Fluorescent Whitening Agents for Polyester

Polyester, being a synthetic fiber, requires a different class of OBAs. Fluorescent whitening agents for polyester are tailored for application on synthetic materials, offering brightness without affecting the fabric’s strength or texture. Gujarat, with its extensive polyester fabric manufacturing zones in cities like Surat and Ahmedabad, has a high demand for polyester-compatible fluorescent brighteners.

Unlike cotton OBAs, those for polyester must resist heat during thermofixation processes and be compatible with hydrophobic surfaces. They are mostly applied via exhaust or pad-dry-cure methods in textile mills.

Role of Textile Brightening Chemicals Manufacturer in Gujarat

The demand for quality Fluorescent Brightener for Textiles Industry in Gujarat is supported by a strong network of textile brightening chemicals manufacturers. These manufacturers develop advanced formulations catering to different fabric types and processing conditions. Gujarat’s chemical manufacturing sector, especially in Ankleshwar, Vapi, and Bharuch, has emerged as a key supplier of OBAs both for domestic and export markets.

These manufacturers ensure:

- High purity and consistency in chemical formulations

- Eco-friendly and REACH-compliant products

- Custom solutions for cotton, polyester, viscose, and blends

- Technical support for application optimization

Application of OBA for Fabric in Textile Mills

The use of OBA for fabric is a common practice in both large-scale textile mills and smaller processing units. The application methods vary depending on the fabric type, machinery, and desired brightness level.

Here’s how OBA is typically applied:

- Exhaust Method: Mostly used for yarn and fabric dyeing, allowing the brightener to exhaust onto the fabric gradually.

- Padding Method: Involves saturating the fabric with a brightener solution and curing it via heat.

- Spray and Foam Techniques: For targeted application or energy-saving processes.

Using OBA ensures uniform brightness, reduces fabric yellowing, and enhances dyeing performance, making the textile product more appealing to both domestic and international buyers.

Brightener Chemicals for Textile Processing: A Game Changer

In today’s highly competitive textile industry, brightener chemicals for textile processing are not just a value addition but a necessity. They help manufacturers in Gujarat meet stringent quality expectations from global brands and retailers.

Advantages of using brightener chemicals include:

- Improved fabric whiteness and color brilliance

- Better compatibility with dyeing and finishing agents

- Enhanced visual appeal and customer satisfaction

- Reduced yellowing during storage and display

Brighteners also contribute to sustainable processing by reducing the need for excessive bleaching, which often harms the environment and the fabric’s tensile strength.

Why Gujarat Leads in Fluorescent Brightener Usage

There are several reasons why Gujarat has become a leader in the use of Fluorescent Brightener for Textiles Industry in Gujarat:

- Strong Textile Infrastructure: Gujarat has thousands of textile mills and processing units.

- Supportive Chemical Manufacturing: The state has robust chemical clusters for raw material supply.

- Export-Oriented Units: Many textile units in Gujarat serve international clients demanding bright, clean finishes.

- Skilled Workforce: Technicians and chemical engineers are well-trained in modern textile processing.

- Government Support: Subsidies, parks, and logistics help the industry adopt high-grade textile chemicals.

Future Outlook for Fluorescent Brighteners in Gujarat

The future of Fluorescent Brightener for Textiles Industry in Gujarat looks promising with rising global demand for sustainable and high-quality textiles. More R&D is being carried out to develop biodegradable OBAs and reduce environmental impact. Gujarat’s textile chemical industry is also moving towards green chemistry and zero-discharge solutions.

As buyers seek brighter and longer-lasting fabrics, the reliance on OBAs and fluorescent whitening agents will only increase. For textile manufacturers in Gujarat, adopting the latest brightener technologies will ensure a competitive edge in both domestic and export markets.

FAQs- Fluorescent Brightener For Textiles Industry In Gujarat

1. What is a fluorescent brightener used for in textiles?

A fluorescent brightener is used to enhance the whiteness and brightness of fabrics by absorbing UV light and emitting blue light, making textiles look cleaner and brighter. Fluorescent Brightener For Textiles Industry In Gujarat

2. Is there a difference between optical brighteners for cotton and polyester?

Yes, cotton requires OBAs compatible with cellulose fibers, while polyester needs brighteners that can bond with synthetic fibers and withstand high heat. Fluorescent Brightener For Textiles Industry In Gujarat

3. Can fluorescent brighteners be used on blended fabrics?

Absolutely. Special formulations are available for blends like poly-cotton or viscose blends, allowing consistent brightness across fiber types.

4. Are fluorescent brighteners eco-friendly?

Many modern OBAs are eco-friendly, biodegradable, and comply with international environmental norms like REACH and OEKO-TEX.

5. Where can I find textile brightening chemicals manufacturers in Gujarat?

Gujarat has several reputed manufacturers and suppliers in cities like Ahmedabad, Surat, Vapi, and Ankleshwar specializing in OBAs for various textile applications.