Fluorescent Brightener for Plastic Industry in India

Table of Contents

- Fluorescent Brightener for Plastic Industry in Gujarat

- What is a Fluorescent Brightener?

- Optical Brightener for Plastic

- OB1 Brightener: The Industry Favorite

- Fluorescent Whitening Agent for Plastic

- Masterbatch Brightener: Enhancing Manufacturing Efficiency

- UV Brightener for Plastic

- Brightener for PVC Fluorescent Brightener for Plastic Industry in Gujarat

- Brightener for PP and PE

- Brightener for PET

- Why Gujarat is a Leader in Fluorescent Brightener Usage

- FAQs- Fluorescent Brightener for Plastic Industry in Gujarat

- Q1. What is the purpose of fluorescent brighteners in plastic?

- Q2. Which fluorescent brightener is best for plastic?

- Q3. Are fluorescent brighteners safe to use in food-grade plastic?

- Q4. Can I use the same brightener for all plastic types?

- Q5. How is a masterbatch brightener different from powder brighteners?

The Fluorescent Brightener for Plastic Industry in India has witnessed remarkable growth over the past few decades, positioning the state as a hub for plastic manufacturing and processing in India. From Ahmedabad to Vapi and Rajkot to Vadodara, Gujarat houses thousands of plastic manufacturing units that rely heavily on additives to improve product quality. One such essential additive is the fluorescent brightener, also known as optical brightener. This compound plays a critical role in enhancing the appearance and brightness of plastic materials, making them more appealing, functional, and market-ready.

Explore:

Optical Brightener Powder for Detergent Industry in Gujarat

Optical Brightening Agents for Paper Industry In India

Fluorescent Brightener For Textiles Industry In Gujarat

What is a Fluorescent Brightener?

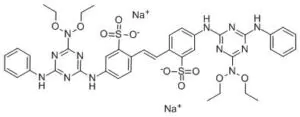

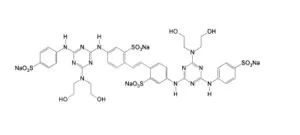

A fluorescent brightener Fluorescent Brightener for Plastic Industry in India, often called an optical brightener, is a chemical compound that absorbs UV light and emits it as visible blue light. This emission neutralizes any yellowish tint and enhances the overall whiteness or brightness of plastic materials. It is widely used in thermoplastics and thermosets to improve visual appeal.

The fluorescent brightener for plastic industry in India is in high demand, thanks to the diverse applications of plastic across sectors like packaging, automotive, electronics, consumer goods, and construction.

Optical Brightener for Plastic

One of the most widely used fluorescent agents is the optical brightener Fluorescent Brightener for Plastic Industry in India. fluorescent brightener for plastic industry in India It’s primarily used to enhance the appearance of plastics by increasing brightness and hiding natural discoloration. Whether you’re producing white goods or colored plastics, an optical brightener ensures that the final product looks vibrant and clean.

Optical brighteners Fluorescent Brightener for Plastic Industry in India are especially important in applications such as:

- Household plastic containers

- Packaging films

- Injection molded parts

- Plastic sheets and profiles

In Gujarat, several manufacturers and suppliers specialize in producing high-quality optical brighteners for plastic, catering to both domestic and international markets.

OB1 Brightener: The Industry Favorite

Among various types of fluorescent brighteners, OB1 Brightener is the most popular for the plastic industry. fluorescent brightener for plastic industry in India Known for its thermal stability, high compatibility with polymers, and strong whitening effects, OB1 Brightener is ideal for applications like:

- Polyester

- Polyamide

- Polypropylene

- Polystyrene

In Gujarat, OB1 is widely used in recycled plastic production to restore the brightness lost during processing. Its cost-effectiveness and long-lasting results make it a go-to solution for manufacturers seeking to enhance product aesthetics.

Fluorescent Whitening Agent for Plastic

Fluorescent whitening agents (FWA) are integral to producing high-clarity and high-luminance plastic items. These agents work by converting UV radiation into visible light, creating a whitening effect.

In Gujarat, plastic manufacturers prefer FWAs for their compatibility with various resins, including:

- PET (Polyethylene Terephthalate)

- PP (Polypropylene)

- PE (Polyethylene)

- PVC (Polyvinyl Chloride)

These fluorescent whitening agents are especially critical in applications where product appearance plays a decisive role—such as packaging films, cosmetic containers, and clear plastic bottles.

Masterbatch Brightener: Enhancing Manufacturing Efficiency

Another common form of fluorescent brightener used in Gujarat’s plastic industry is the masterbatch brightener. This is a concentrated mixture of fluorescent brightener and polymer carrier resin, making it easier to dose and mix during plastic production.

Advantages of masterbatch brighteners include:

- Uniform dispersion

- Lower wastage

- Improved production efficiency

- Minimal dusting during handling

Manufacturers in Gujarat often prefer masterbatch form for bulk production, especially when working with recycled plastics or colored resins that need enhanced brightness.

UV Brightener for Plastic

Exposure to sunlight can degrade plastic, leading to discoloration and fading. To combat this, many manufacturers in Gujarat add UV brighteners for plastic. These additives not only enhance brightness but also offer UV protection, increasing the lifespan of outdoor plastic applications.

Applications include:

- Outdoor furniture

- Garden accessories

- Greenhouse films

- Construction materials

With Gujarat’s high exposure to sunlight, UV brighteners play a dual role in both aesthetic enhancement and UV protection.

Brightener for PVC Fluorescent Brightener for Plastic Industry in India

PVC (Polyvinyl Chloride) is one of the most used polymers in India, especially for pipes, window profiles, and sheets. However, PVC tends to yellow over time. A brightener for PVC effectively counteracts this yellowing and keeps the product looking fresh and white.

In fluorescent brightener for plastic industry in India many industries use fluorescent brighteners for rigid and flexible PVC, particularly in the building and construction sector.

Brightener for PP and PE

Polypropylene (PP) and Polyethylene (PE) are used in everything from packaging to toys and household items. Brighteners for PP and PE improve the visual appeal, especially for light or white-colored products.

These polymers benefit significantly from OB1-type brighteners due to their excellent thermal resistance. Fluorescent Brightener for Plastic Industry in India-based plastic units processing PP and PE use fluorescent brighteners to stay competitive in appearance and quality.

Brightener for PET

PET is widely used for bottles and textile fibers. A brightener for PET not only enhances the clarity of the final product but also reduces yellowing during the reprocessing of recycled PET flakes fluorescent brightener for plastic industry in India.

Many plastic industries in Gujarat engaged in PET recycling rely on fluorescent brighteners to improve product value and appeal.

Why Gujarat is a Leader in Fluorescent Brightener Usage

Gujarat’s prominence in the plastic sector is due to:

- A large number of plastic processing units

- Easy access to raw materials

- Pro-business policies

- Strong export capabilities

This ecosystem fuels the demand for high-quality fluorescent brighteners for the plastic industry in Gujarat, making the state a hotbed for innovation and manufacturing in this niche.

FAQs- Fluorescent Brightener for Plastic Industry in India

Q1. What is the purpose of fluorescent brighteners in plastic?

A1. Fluorescent brighteners enhance the brightness and whiteness of plastic products by absorbing UV light and re-emitting it as visible blue light, masking yellow tones and improving aesthetic appeal.

Q2. Which fluorescent brightener is best for plastic?

A2. OB1 Brightener is widely used due to its high thermal stability and strong whitening effects. It works well with various plastics like PET, PP, PE, and PVC.Add Image

Q3. Are fluorescent brighteners safe to use in food-grade plastic?

A3. Yes, but only specific grades of fluorescent brighteners that meet food-contact regulations should be used. Always consult with your supplier regarding FDA or EU compliance.

Q4. Can I use the same brightener for all plastic types?

A4. Not necessarily. Different polymers may require different types of brighteners based on processing temperature and material compatibility. OB1 is versatile but not universal.

Q5. How is a masterbatch brightener different from powder brighteners?

A5. Masterbatch brighteners are pre-dispersed in a carrier resin, making them easier to handle and ensuring uniform distribution. Powder brighteners may offer cost benefits but require careful mixing.